Metal building panel types vary widely in structure and performance, and selecting the right option requires aligning technical requirements with project constraints. Panels are typically grouped by construction method (single-skin, insulated, or composite), geometry (such as corrugated or ribbed profiles), and application (exterior cladding or interior liners).

Key specifications include yield strength, coating class (e.g., PVDF, SMP), R‑values or U‑factors, water penetration and air leakage ratings, fire classifications, and corrosion resistance per environment. Misalignment can raise lifecycle cost or risk code noncompliance; the distinctions are not always obvious.

Metal building panels are commonly categorized by structural construction, material, and application role.

By structural construction, panels are defined as single-skin, insulated sandwich (IMPs), or composite, each governed by distinct load paths, fastening strategies, and serviceability limits per project specifications and applicable codes.

By material, steel, aluminum, and specialty alloys are selected using yield strength, corrosion class, and coating system (e.g., PVDF, FEVE) to meet durability and color-retention requirements.

By application role, metal wall panel systems, roofing, soffit, and rainscreen assemblies are specified to achieve thermal, air, water, and fire performance targets.

Architectural metal panels are differentiated from utilitarian cladding by flatness tolerance, joint fidelity, and finish warranties.

Prefabricated wall panels reduce site variability, supporting schedule control and consistent QA/QC through factory detailing and tested assemblies.

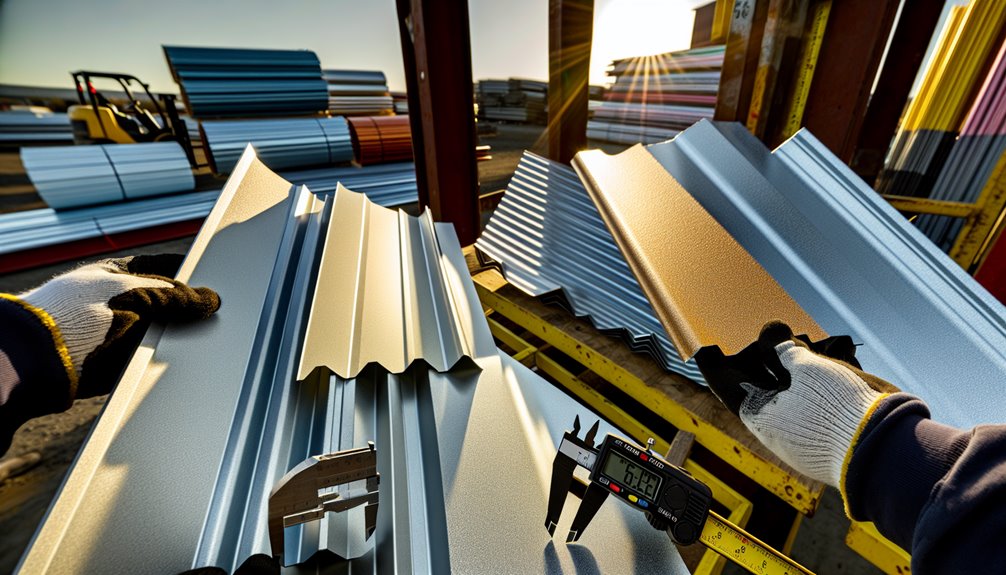

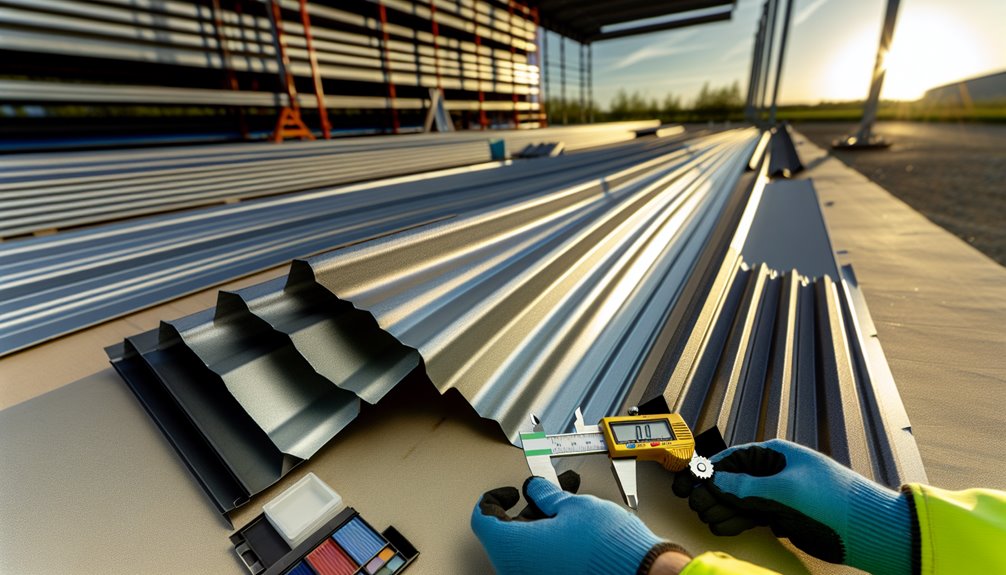

Single-skin metal panels are single-layer steel or aluminum sheets whose structural performance is derived from profile geometry (e.g., ribs, corrugations) rather than composite action.

As a subset of metal building panel types, these lightweight metal panels are specified where simple construction, rapid installation, and lower initial cost are priorities, particularly for industrial and utility buildings.

Typical applications include roofing and exterior metal wall panels with exposed or concealed fastener systems conforming to project wind, snow, and seismic criteria.

Key considerations: limited flatness over large spans, elevated risk of oil canning, and potential deformation under localized loads.

Performance selection should reference certified test data (e.g., ASTM E1592 for wind uplift, AISI S100 for cold-formed design) and coating/compliance requirements (e.g., ASTM A653/A792, AAMA 2605) to maintain control over durability, appearance, and lifecycle.

Although often grouped by shape, profiled metal panels—corrugated, ribbed, and similar geometries—are defined by their formed profile rather than inherent performance. Corrugation and ribbing increase panel stiffness in thin gauges, benefiting metal cladding systems used on industrial buildings and warehouses. Selection should be driven by drainage path, aesthetics, and fastener strategy (exposed vs concealed), not just the wave or rib height. For commercial metal wall panels and structural wall panels, verify section properties, tested spans, and code approvals.

| Attribute | Control Consideration |

|---|---|

| Profile geometry | Determines moment of inertia, deflection limits, and oil-canning risk |

| Fastener exposure | Drives watertightness, maintenance, corrosion points |

| Drainage path | Controls panel orientation, lap details, and runoff velocity |

| Substrate/support | Affects allowable spans, pull-out, and diaphragm values |

| Coating/alloy | Impacts durability, UV stability, and lifecycle cost |

Insulated metal panels (IMPs) are factory-fabricated sandwich assemblies consisting of two metal facings bonded to a rigid foam core, engineered to deliver high thermal performance and rapid enclosure.

As engineered panel systems, they provide predictable U-values, airtightness, and accelerated dry-in, reducing trades and thermal bridging. Typical applications include temperature-controlled buildings, logistics hubs, and energy-efficiency-driven projects where speed and envelope continuity are prioritized.

Specification focus includes panel thickness to meet target R-values, interlocking joint geometry for water/air barriers, and compliance with NFPA 285 (where applicable), FM/UL listings, and IBC wind, seismic, and combustibility requirements.

Limitations include thicker build-up and profiles less suitable for refined interior metal wall panels or decorative systems. Coordination of penetrations, sub-framing, and fastener patterns is essential to maintain thermal, structural, and air/vapor performance.

Composite metal panels consist of two thin metal face sheets bonded to an engineered core, delivering high stiffness-to-weight ratios and superior flatness compared to single-skin panels.

Performance hinges on core selection: mineral-filled or A2 cores elevate fire resistance and reduce smoke development; low-density thermoplastic cores minimize weight but reduce stiffness and fire ratings; structural cores increase modulus and improve fastener pull-through capacity.

Flatness and dimensional tolerances support crisp façade alignments and tight joint reveals.

Common applications include commercial façades, podium levels, shared spaces, and semi-decorative exterior walls where uniformity and controlled deflection are required.

Specifiers should verify product testing to NFPA 285 (assembly), ASTM E84/UL 723 (surface burning), ASTM E330 (structural performance), and AAMA 2605/FEVE or PVDF coating standards, while confirming wind loads, substrate compatibility, and warranty terms.

Honeycomb metal panels use an engineered honeycomb core bonded between thin metal face sheets to deliver high stiffness-to-weight ratios, exceptional flatness, and long-span capability with reduced dead load.

This structure offers superior rigidity without heavy subframing, enabling large-format modules and precise tolerances. Long-term dimensional stability limits oil-canning and thermal bow.

Typical applications include modern civic, transportation, and institutional buildings where flatness and alignment control are critical.

Specifiers should verify testing to ASTM E330 (structural), E283/E331 (air/water), and NFPA 285 where applicable, plus confirm finish performance to AAMA 2605.

From high-stiffness façade modules to everyday building envelopes, metal side cladding panels address lateral exposure zones with defined performance targets for durability, replaceability, and serviceability.

Typical use cases include building sides, corridors, podiums, and service zones where panels must deliver impact resistance and controlled maintenance cycles. Specifiers prioritize dry construction methods, aiming for fast installation and straightforward panel swap-out to minimize downtime.

System selection emphasizes quantifiable criteria: panel gauge and rib geometry for stiffness; coating system per AAMA 2605 or equivalent for UV and corrosion resistance; and attachment systems tested to ASTM E330/E331 for wind and water performance.

Prioritize measurable specs: gauge and rib stiffness, AAMA 2605 coatings, and ASTM E330/E331-tested attachments.

In high-traffic areas, impact ratings (e.g., ASTM D5420) support defensible detailing. Designs target accessible fixings, modular dimensions, and standardized trims to reduce long-term disruption and guarantee predictable lifecycle costs.

Although both are specified across similar envelopes, steel and aluminum panels diverge on stiffness, mass, corrosion behavior, and lifecycle coatings.

Steel delivers higher modulus-driven rigidity and superior dent/impact resistance at equal thickness, supporting longer spans and tighter deflection limits.

Aluminum reduces dead load, easing subframing demands and transport, while offering inherent corrosion resistance, especially in marine or de-icing salt exposure.

Durability for both materials is strongly governed by coating systems; PVDF topcoats with G90/Galvalume substrates (steel) and conversion-coated, anodized, or PVDF systems (aluminum) should be selected per AAMA/ASTM performance data and project corrosivity category.

Material selection for steel versus aluminum sets the baseline, but performance requirements diverge markedly once panels move indoors or outdoors.

Interior panels prioritize flatness (visual tolerances), fire performance (per IBC/ASTM E84, NFPA 285 where applicable), and cleanability (smooth finishes, low-VOC coatings, antimicrobial options). They often use single-skin or MCM with tight tolerances to limit oil-canning and may specify washable polyester or powder coatings.

Exterior panels prioritize weather resistance (air-water barriers, ASTM E283/E331), corrosion protection (zinc/aluminum-zinc coatings, PVDF/FEVE), and thermal movement accommodation (slotted fasteners, clip systems).

Standing seam and PBR profiles manage wind uplift (FM/UL, ASCE 7) and precipitation. The same panel type can perform differently by location: interior uses relax expansion detailing and UV stability; exterior assemblies require robust sealants, drainage planes, and tested attachment systems for climate-specific loads.

Which panel profile best meets performance criteria depends on quantified project demands: required module size and surface flatness tolerances (to control oil‑canning), applicable fire ratings and test standards (IBC chapter references, ASTM E84/NFPA 285 where triggered), structural load resistance per ASCE 7 and manufacturer span tables, attachment methodology (dry clip/standing seam vs wet sealant systems) validated by ASTM E283/E331 air-water tests, and a defined maintenance/replacement plan that considers exposed vs concealed fasteners, access, and lifecycle coating durability (PVDF/FEVE vs polyester).

Selection then aligns profiles to metrics:

Align panel profiles to quantified metrics for loads, fire, and maintenance constraints.

They perform variably: marine-grade aluminum, stainless (316), and PVDF-coated steel meet ASTM B117 salt-spray resistance with proper edge sealing. Specify concealed fasteners, heavy zinc/aluminum-magnesium coatings, and robust underlayment. Enforce AAMA 2605, ISO 12944 C5, and rigorous maintenance/inspection schedules.

Yes, but only per panel type, gauge, span, and fastening pattern per manufacturer’s foot-traffic rating—footprints as calibrated loads on a bridge. Use designated walk pads, purlin paths, ASTM E1592/CSA S136 compliance, fall protection, and distribute loads.

UL 2703 governs mounting systems; fire classifications must match roof covering per UL 790/ASTM E108. Compliance requires listed assemblies, proper standoff/rails, and maintained firebreaks. NEC 690, IFC/IBC mandate setbacks, pathways, labeling, and module/system listings for roof fire performance.

Cut to the chase: Panel profiles and cores govern absorption, transmission loss, and flanking. IMPs with foam cores improve NRC/STC; perforated single-skin with mineral wool meets ASTM C423. Seal seams, decouple subframing, and detail penetrations per ISO 10140.

Metal panels are highly recyclable; steel and aluminum achieve 855% reclamation via established scrap streams. End-of-life options include direct recycling, IMP foam separation, take-back programs, and reuse per ISO 14001/14044, LEED v4 MR, and EN 15804 end‑of‑life scenarios.

Selecting metal building panels is a standards-driven exercise, not guesswork. By comparing single-skin, profiled, insulated, and composite systems against quantified criteria—U-values, fire classifications (e.g., EN 13501-1, ASTM E84), wind and impact ratings, corrosion class (ISO 12944), and maintenance cycles—specifiers align performance with project risk. Like tuning a calibrated instrument, the right panel harmonizes structure, energy efficiency, durability, and compliance, ensuring lifecycle value through measurable metrics, documented test data, and code-conforming assemblies for interior and exterior applications.