Choosing between aluminium and steel honeycomb panels depends on weight targets, structural loads, durability needs, and lifecycle cost. Aluminium offers lower density and transport savings; steel delivers higher impact resistance and local bearing strength. Both achieve high stiffness-to-weight ratios per ISO 12215 and EN 14509 principles, but differ in corrosion behavior, flatness at scale, and fire performance classifications. Material and fabrication costs vary with gauge, core cell size, and coatings. The trade-offs become clearer with specific project scenarios.

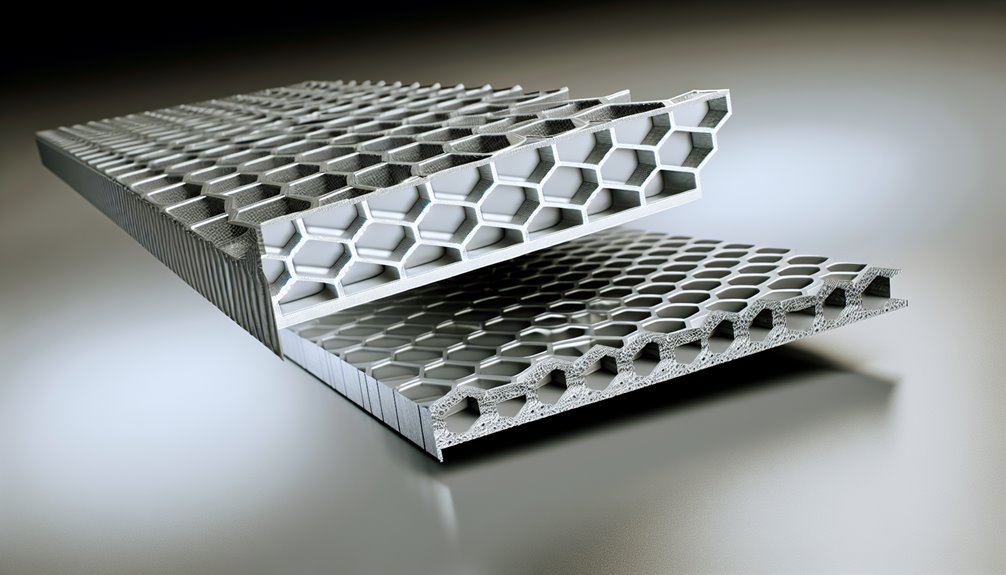

Despite differences in skin materials, both aluminum and stainless steel honeycomb panels share a common architecture: thin face sheets adhesively bonded to a lightweight cellular core that distributes load efficiently.

This shared topology underpins the aluminium honeycomb panel system and the steel honeycomb panel system alike, enabling high surface flatness across large-format modules. The core geometry is constant; only material behavior varies, so performance comparisons should control for cell size, foil gauge, and adhesive specification.

Shared topology ensures high flatness; compare performance by controlling cell size, foil gauge, and adhesive specification.

Both systems are engineered for façades, interiors, transport hubs, and public buildings, where tolerances for planarity and dimensional stability are codified by project QA plans and relevant façade standards.

Adhesive bonds are validated by peel-strength testing and environmental conditioning, ensuring consistent bondline integrity and predictable in-plane shear transfer.

Weight is often the first constraint that shapes panel selection. Aluminium honeycomb panels offer substantially lower density and panel mass than steel-skinned honeycomb panels, which directly reduces dead load on the primary structure, secondary framing, and fixings. In aluminium vs steel honeycomb panels, this density gap quickly cascades into larger design implications—affecting frame sizing, anchor quantity, crane capacity, and installation logistics.

Lighter aluminium panels typically allow smaller fasteners, lighter secondary steel, and faster handling on site. Transport efficiency also improves, with lower fuel use, reduced crew effort, and lighter lifting equipment classes. By contrast, steel-skinned honeycomb panels introduce higher dead loads and increased substructure demands, which may be justified only where surface durability or impact resistance takes priority over weight control.

For high-strength composite panels, weight budgeting should be evaluated independently from strength considerations and aligned with code-governed load combinations and deflection limits, rather than assumed material toughness.

| Metric | Aluminium Honeycomb Panels | Steel-Skinned Honeycomb Panels |

|---|---|---|

| Relative density | Low | Moderate to high |

| Dead load impact | Minimal | Significant |

| Installation & handling | Light-duty equipment | Heavier lifting equipment |

Decision rule: when structural weight, handling efficiency, or large-format panels matter, aluminium is the default choice.

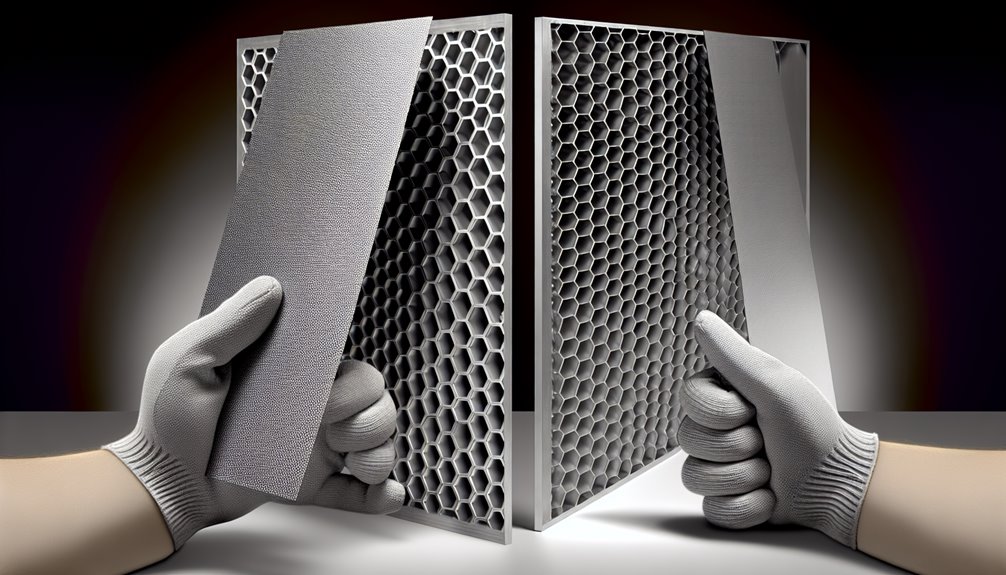

While both panel types leverage the honeycomb core for stiffness and flatness, material skins govern toughness and impact performance.

In metal sandwich panels with a structural honeycomb core, stainless steel skins deliver higher yield strength and hardness, translating to superior resistance to impact, denting, and surface damage in high-traffic zones.

Aluminum skins, though lighter with an excellent strength-to-weight ratio, rely more on core geometry to achieve panel rigidity.

For design to recognized standards, specify face-sheet thickness, alloy/grade, core cell size, and adhesive system; verify by drop-weight impact, dent depth, and residual flexural stiffness per relevant test methods.

Where service includes tool strikes, carts, or debris, steel-faced panels provide higher margin.

For weight-critical applications with moderate abuse, aluminum-faced panels remain efficient.

Flatness in large-format honeycomb panels is governed by face-sheet stiffness, core shear modulus, and self-weight-induced deflection.

In architectural honeycomb panels, aluminum skins on an aluminum core achieve superior flatness over large spans due to lower mass per unit area, reducing creep and long-term sag.

For large format wall panels targeting tight waviness tolerances (e.g., mm over 3 m), aluminum configurations meet criteria with standard face gauges and typical 3003/5052 cores.

Steel-faced panels, while strong, demand thicker face sheets or reduced module sizes to reach equivalent visual flatness, increasing weight and subframing demands.

Designers should validate flatness per ASTM C365/C393 stiffness data and project-specific deflection limits.

For seamless façades and interior feature walls, aluminum offers greater layout flexibility and consistent panel plane.

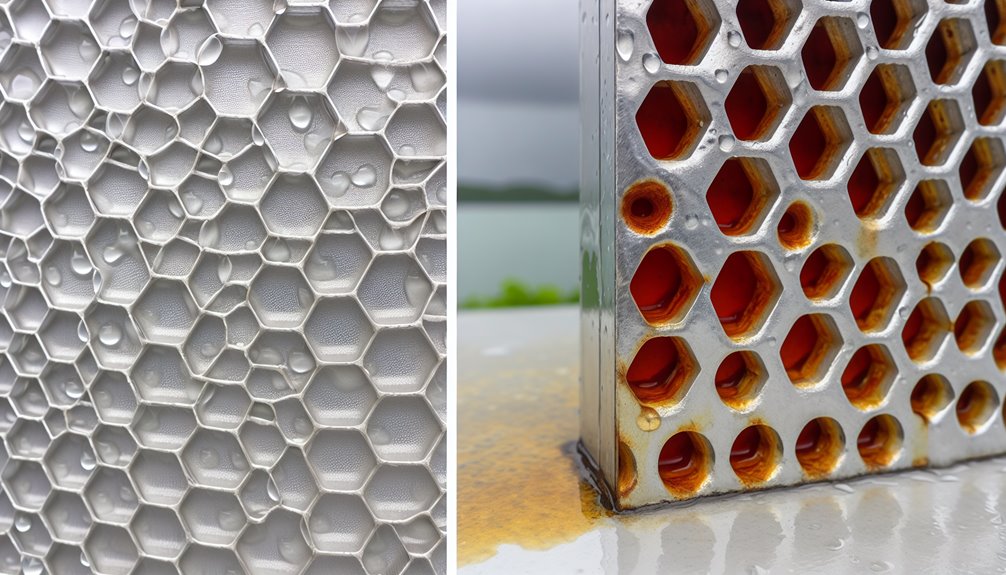

Despite similar sandwich constructions, corrosion behavior differs markedly by face-sheet material and environment. Aluminum face sheets form a stable Al2O3 oxide, providing inherent protection without reliance on applied films.

Steel face sheets depend on galvanization or multi-coat systems; performance is coating-system dependent. Field data show most failures initiate at coatings and cut edges rather than within the honeycomb core, so edge sealing and system maintenance per ISO 12944 and AAMA 2605 are decisive.

For lightweight wall panel systems and exterior architectural panels in coastal, humid, or chemically aggressive zones, aluminum assemblies reduce risk and upkeep.

In benign urban exposures, coated or galvanized steel is viable with disciplined QA: specified zinc mass, DFT verification, and cut-edge treatment. Selection should align the exposure category, inspection interval, and lifecycle corrosion allowance.

Although face-sheet alloy influences thermal response, the fire performance of honeycomb panels is governed by the certified assembly—core, adhesive, skins, and coatings—evaluated to recognized standards.

Specifiers should reference objective test data (EN 13501-1, ASTM E84, NFPA 285, EN 13823/SBI) tied to the exact construction. Steel skins typically retain strength longer under extreme heat, but material alone does not determine rating; the adhesive and core drive combustibility, smoke, and heat release.

Aluminum honeycomb panels are widely approved when correctly certified, including for interior decorative wall panels, provided adhesives are low-heat-release and coatings meet smoke/toxicity limits.

Require third-party listings, documented assembly drawings, and traceable QA. Match classification (A1/A2, Class A, or compliant NFPA 285 wall system) to occupancy and height, and verify local code equivalencies before procurement.

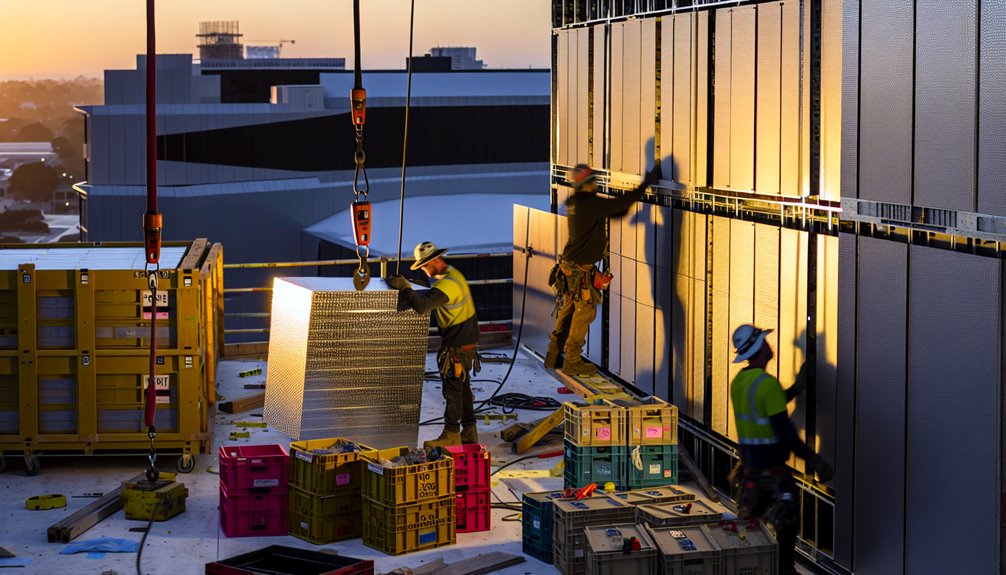

When installation sequencing prioritizes speed and minimal site disruption, aluminum honeycomb panels typically outperform stainless steel due to lower unit weight, reduced need for lifting gear, and faster dry-fit cycles.

Crews can manually handle more aluminum units per hour, reducing crane picks and staging time, and accelerating progress on unitized facades and interior fit-outs. In dry systems, aluminum enables shorter adjustment windows and quicker tolerance verification with standard anchors and sub-framing.

Stainless steel honeycomb panels increase handling complexity. Heavier modules require more rigging, additional personnel, and stricter lift plans, elongating set times per panel.

On constrained sites, hoist frequency and laydown turnover slow, extending critical-path durations. Method statements, toolbox talks, and manual handling limits favor aluminum where schedule certainty, rapid elevation turnover, and minimized plant utilization are prioritized.

Material unit rates rarely reflect the true cost impact of honeycomb panel selection. While aluminium honeycomb panels may carry a higher price per square metre, overall project economics often improve through downstream efficiencies. Reduced panel weight lowers structural reinforcement requirements, simplifies rigging, and shortens installation windows—compressing labour, crane time, and site coordination costs.

By contrast, steel honeycomb panels can appear materially competitive at first glance, but frequently introduce indirect cost drivers. Heavier panels increase demands on secondary framing, anchor density, and lifting capacity, extending installation duration and elevating site logistics costs. Over time, maintenance profiles also diverge: in architectural applications, lifecycle assessments commonly favour aluminium systems, particularly where appropriate coating specifications mitigate corrosion exposure.

For accurate comparison, decision-makers should evaluate total installed cost (TIC) and net present cost (NPC) using standards-based assumptions for load combinations, environmental exposure, and service life—rather than relying on material price alone.

| Cost Driver | Aluminium Honeycomb Panels | Steel Honeycomb Panels |

|---|---|---|

| Structural impact | Lighter subframing | Added reinforcement |

| Installation duration | Shorter, fewer lifts | Longer, heavier lifts |

| Lifecycle cost | Typically lower | Higher in many cases |

Decision principle: cost control follows measured, system-level evaluation—not unit pricing.

Across building and transport sectors, aluminium honeycomb panels are specified where low mass, high flatness, and tested fire and acoustic performance are required—typical deployments include commercial façades and interior wall systems, airports and transport hubs, hospitals, and other public buildings.

Specifiers select these panels to meet tight deflection limits, reduce substructure loads, and achieve consistent planarity for large-format cladding and lining. Typical projects prioritise EN/ASTM-validated fire performance, vibration damping, and cleanability.

Although aluminum offers superior mass efficiency, stainless steel-skinned honeycomb panels are specified where surface hardness, impact resistance, and chemical resilience govern performance: high-impact zones, industrial plants, transport infrastructure, and service corridors/back-of-house.

Their stainless skins deliver higher scratch resistance and Hertzian contact strength, protecting against carts, trolleys, and vandalism. In process areas, stainless resists caustics, solvents, and steam cleaning, sustaining finish and hygiene. For platforms, tunnel linings, and platforms/concourses, the heavier section improves dent resistance and service life under frequent contact.

Typical specifications target high peel strength between stainless face sheets and aluminum honeycomb using high-temperature-curing polyurethane adhesives, ensuring panel flatness and durability.

Compliance with corrosion categories (e.g., C4–C5 environments), cleanability requirements, and impact criteria (pendulum or drop-weight tests) supports predictable lifecycle and maintenance control.

When selecting between aluminum and stainless steel honeycomb panels, decisions should be anchored in quantified project requirements: weight limits (e.g., floor live-load budgets and handling logistics), exposure class per ISO 12944 or similar (C3 vs C4–C5), panel span and format (deflection and flatness over large modules), impact and surface hardness needs (scratch, dent, and Hertzian contact resistance), and maintenance regime (cleaning chemicals, steam, expected touch-up frequency).

Aluminum favors projects constrained by lifting capacity and installation speed; stainless steel suits high-abuse, chemically aggressive zones.

To decide, verify the following:

Aluminium honeycomb panels support PVDF or FEVE coatings, anodised finishes, brushed textures, woodgrain effects, and RAL colour matching. Steel honeycomb panels are available in satin (No.4), hairline, mirror, bead-blasted, and PVD colour finishes. Both materials can achieve high flatness, controlled gloss, and stable colour performance.

Maintenance differs by alloy: stainless steel skins need detergent wipe-downs, chloride control, and ASTM A380/A967 passivation checks; aluminum requires neutral-pH cleaning, periodic coating inspection, and galvanic isolation. Lifespan plans should include scheduled peel-strength testing and sealant joint audits.

Long-term integrity relies on two-component, high-temperature curing polyurethane or epoxy adhesives, chemically treated bonding surfaces, and hot-press composite methods. Process controls include surface energy verification, ASTM C297/C633 adhesion tests, peel-strength per ISO 11339, controlled cure cycles, humidity/thermal cycling validation, and substrate roughness specifications.

Yes. He cites recyclability via ISO 14001 systems, EPDs per EN 15804/ISO 14025, LEED/BREEAM credits, REACH/RoHS compliance, take-back programs, metal scrap streams, FSC-free packaging options, and end-of-life disassembly documentation, with chain-of-custody, material declarations, and lifecycle assessments.

Aluminium honeycomb panels typically ship in 2–4 weeks, while steel panels often require 4–6 weeks. Customisation options include panel thickness, core size, skin gauge, finishes, perforations, edge details, and fire ratings.

Choosing between aluminium and steel honeycomb panels depends on measurable project needs—weight limits, panel span, impact exposure, and environmental conditions. Aluminium favours lightweight construction and large-format flatness, while steel suits impact-prone or industrial settings. In most projects, the total cost of ownership—including installation and maintenance—matters more than material price alone.

For project-specific guidance on selecting and specifying honeycomb panel systems, Phili Green Panels provides technical support from material selection through system detailing. Contact us to discuss your application requirements.