In today's rapidly evolving construction and design industries, commercial wall panel systems stand out as a pivotal element, blending functionality with aesthetic appeal. These systems, which range from high-pressure laminates to reinforced fiberglass, offer not only a diverse array of finishes and styles but also promise significant improvements in installation efficiency and lifecycle costs. As architects and designers continually seek innovative solutions to meet stringent regulatory standards and client expectations, understanding the spectrum of available wall panel systems becomes crucial. Let us explore how these systems can transform both the form and function of commercial spaces, and why they are increasingly becoming a cornerstone in contemporary architectural design.

As the commercial construction industry embraces sustainability, wall panel systems are increasingly pivotal. These systems are spearheading a revolution that merges aesthetic appeal with environmental stewardship and enduring performance. Companies like Philigreen are leading this transformation by deploying next-generation sustainable materials, which include low-carbon production processes, recyclable and non-toxic components, and energy-efficient manufacturing. This approach not only supports the environmental goals of projects but also caters to the evolving demands of modern commercial architecture.

Philigreen's innovations extend beyond materials to smart integration capabilities. Their prefabricated systems enhance installation speed, integrate built-in acoustic and thermal properties, and ensure seamless compatibility with IoT building technologies. Such features make these wall panels not just functional but integral to creating intelligent building environments.

Furthermore, these systems are designed to meet rigorous standards for safety and durability. Philigreen's wall panel systems offer advanced fire resistance up to A2-s1,d0 standards, hospital-grade hygienic surfaces, and military-grade durability, making them suitable for high-traffic commercial spaces.

These attributes ensure that the wall panels not only meet today's construction needs but are also future-proof, aligning with green building certifications like LEED and WELL, thus shaping the sustainable commercial spaces of tomorrow.

Building on the innovative strides made by companies like Philigreen in the commercial construction sector, it is important to understand exactly what commercial wall panel systems are. These systems are engineered cladding solutions tailored for high-performance environments such as corporate offices, hospitality venues, healthcare facilities, and public spaces.

Unlike conventional construction methods like drywall or tiling, commercial wall panels are prefabricated, integrating durable materials into modular designs that not only appeal aesthetically but are also built to last.

Commercial wall panels are typically manufactured off-site in controlled factory settings before being transported to construction sites. This prefabrication allows for rapid assembly and installation, which significantly cuts down construction times and costs.

Moreover, these panels are designed to connect seamlessly, ensuring a consistent and streamlined appearance that enhances the external facade of any building.

One of the standout benefits of using commercial wall panel systems is their superior insulation properties. By improving thermal resistance, these panels help in reducing the energy costs associated with heating and cooling, making them a cost-effective and environmentally friendly building solution.

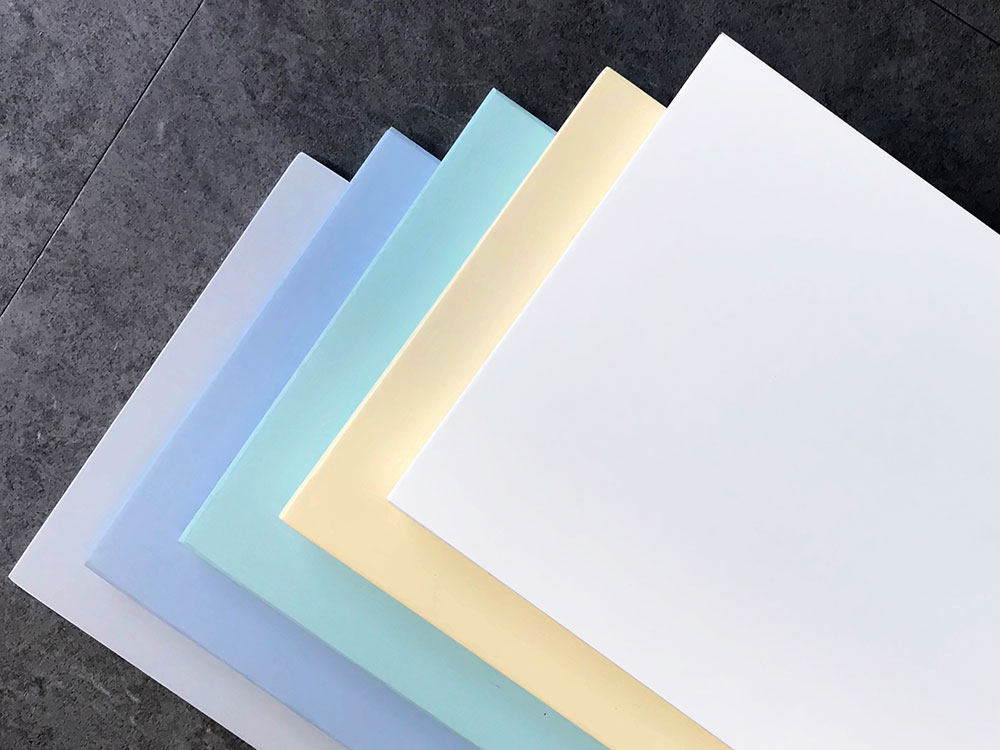

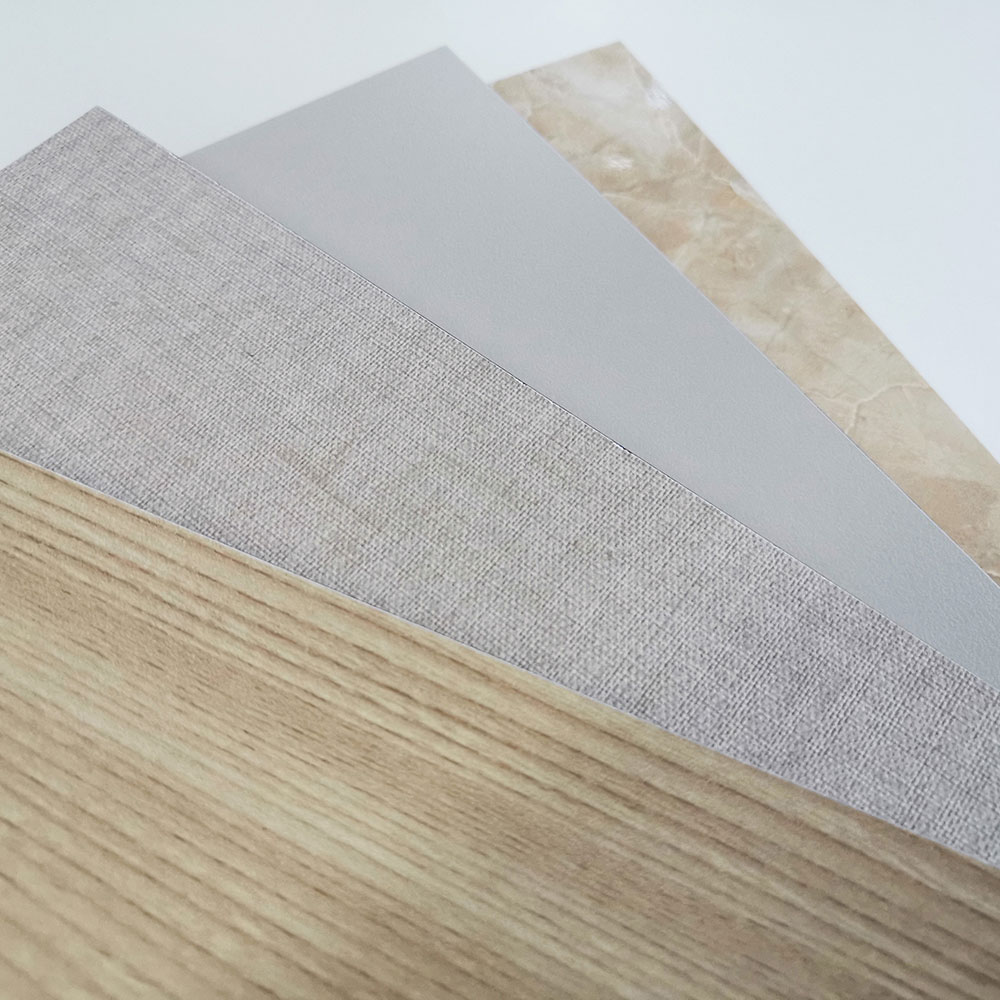

Commercial wall panel systems engineered by Philigreen are distinguished by their exceptional range of materials and finishes, designed to meet diverse architectural and environmental demands.

At the core of Philigreen's offerings are advanced polymer composites, which include high-density PVC cores, impact-resistant honeycomb aluminum matrices, and mineral-reinforced substrates based on magnesium oxide. These core materials are complemented by metal hybrid systems that feature powder-coated aluminum faces, galvanized steel backings with anti-corrosion treatments, and elegant copper and brass veneer options.

Philigreen also emphasizes sustainability with its recycled content panels, which boast up to 89% post-industrial material, and rapidly renewable bamboo substrates. These innovations are not only eco-friendly but also meet rigorous standards, as evidenced by their Cradle-to-Cradle certifications.

The surface finishes of Philigreen panels enhance both function and aesthetics. Options include 3D nano-ceramic coatings for exceptional scratch resistance, antimicrobial surfaces impregnated with silver ions, and UV-cured fluoropolymer topcoats.

Aesthetically, Philigreen offers real wood veneers, high-resolution digital prints, and a variety of architectural metal patinas, alongside technical performance finishes like electromagnetic shielding and photocatalytic air-purifying coatings. These comprehensive material and finish options ensure that Philigreen's wall panels excel in both performance and design.

Understanding the diverse material and finish options available in commercial wall panel systems sets the stage for exploring their practical applications across various industries.

In healthcare and medical facilities, where hygiene is paramount, engineered panels such as Philigreen's BioGuard® Panels are crucial. These panels are used in hospital patient rooms, ICUs, surgical suites, and cleanrooms due to their antimicrobial surfaces and chemical resistance, ensuring a sterile environment.

In the hospitality sector, particularly luxury hotels, aesthetic appeal and durability are essential. Wall panels such as LuxClad® offer luxury finishes and sound-dampening properties, making them suitable for hotel lobbies, elevator interiors, and restaurant kitchens. Their vandal-resistant features maintain the pristine condition of these high-traffic areas.

Corporate and office spaces benefit from the modular and reconfigurable nature of wall panels like MagneSurface®, enhancing dynamic work environments through writable and magnetic surfaces in executive offices and conference rooms.

Retail spaces utilize high-impact visual panels like PrintFlex® for branded store fixtures and mall column wraps, combining aesthetic appeal with easy maintenance.

Lastly, transportation and public infrastructure demand robust solutions like those used in airport terminals and subway stations, where durability and weatherproofing are critical.

These applications showcase the versatility and essential role of commercial wall panel systems in modern architecture and design.

While traditional construction methods have their place, modern commercial wall panel systems offer a range of benefits that significantly enhance building performance, sustainability, and aesthetic versatility. Philigreen's advanced panel solutions, such as the ArmorClad® and EcoCore® systems, showcase how these benefits are materialized across various commercial settings.

The table below summarizes the key advantages of using modern wall panel systems:

| Benefit Category | Specific Advantage | Ideal Applications |

|---|---|---|

| Durability & Longevity | Nano-coated, impact and abrasion-resistant | High-traffic areas like hospitals |

| Hygiene & Safety | Antimicrobial, fire-rated, easy-to-clean | Hospitals, labs, public transport |

| Sustainability | Low-carbon, recyclable, LEED compliant | Eco-conscious construction projects |

| Cost Efficiency | Faster installation, minimal maintenance | Budget-sensitive developments |

| Design Flexibility | Custom finishes, modular designs | Customizable commercial interiors |

Philigreen's wall panel systems are designed not only to meet the demanding functional requirements of modern buildings but also to offer cost-effective and environmentally friendly solutions. These panels significantly reduce construction waste and lifecycle costs, making them a smart choice for any project looking to combine aesthetics with practicality and sustainability.

Having explored the myriad benefits of modern wall panel systems, the next step is selecting the right type for your specific project needs.

Begin by defining your project requirements, including the application—be it healthcare, hospitality, or retail—alongside specific performance needs like fire resistance or acoustics, as well as aesthetic goals and budget considerations. For instance, hospitals often prioritize hygiene and cleanability, while hotels may focus on luxury aesthetics and durability.

Next, evaluate the core material options available. For environments requiring high hygiene, such as hospitals or labs, High-Pressure Laminate (HPL) or PVC-based panels offer excellent solutions due to their resistance to scratches and seamless joints.

For fire-rated applications or exterior walls, consider inorganic mineral composites for their non-combustible properties. Aluminum honeycomb could be your pick for lightweight yet strong partitions.

Select the right surface finish tailored to the intended function of the space. Nano-ceramic coatings are ideal for high-traffic areas, while antimicrobial surfaces suit hygienic environments perfectly.

For aesthetic versatility, options range from full-color digital printing to real wood veneers.

Lastly, verify necessary compliance and certifications like fire safety and sustainability to ensure the panel system meets all regulatory requirements and supports your project's long-term success.

What can you expect during the installation and maintenance phases of commercial wall panel systems?

Pre-installation planning is crucial, involving substrate inspection to ensure walls are plumb, dry, and structurally sound. An acclimation period of 24-48 hours is necessary for panels to adjust to room temperature.

Layout mapping helps plan for seams, transitions, and cutouts, while proper material handling requires suction lifters for large panels. Philigreen offers digital templating and pre-cut kits for efficient installation.

The installation process includes setting up a framework using light-gauge steel or aluminum studs, with Philigreen's SnapTrack® system reducing framing time by 30%.

Panels are then placed using either adhesives for a seamless appearance or mechanical fasteners for demountable systems. Joint treatments and trim work follow, significantly cutting down installation time—about 50-70% faster than traditional methods, with a 10,000 sq. ft. project potentially wrapping up in just 5-7 days.

Maintenance involves regular cleaning, varying by surface type: HPL/laminate panels require a mild detergent weekly, antimicrobial surfaces need daily hospital-grade disinfectants, and metallic finishes are best cleaned monthly with ammonia-free glass cleaner.

For common installation challenges like warping or adhesive failure, storing panels properly and ensuring clean, aligned substrate preparation are essential.

Philigreen's technical representatives provide on-site support to address any issues during critical phases.

Silencing the cacophony of daily operations, commercial wall panels effectively dampen noise. Their acoustic properties improve sound quality within spaces, thereby fostering a more focused and serene environment in various business settings.

Yes, there are eco-friendly options available in wall panel materials. These include panels made from recycled materials, sustainable wood, and low-VOC composites, which contribute to better environmental sustainability and indoor air quality.

Commercial wall panels, the stalwarts of construction, generally boast a lifespan of 20 to 30 years. Durability can extend with premium materials and regular maintenance, adapting to the evolving demands of architectural structures.

Yes, modern wall panels can support digital and smart technology integrations, such as embedded screens and control systems, enhancing functionality in commercial spaces by facilitating digital displays and interactive features.

In a hypothetical office fire, non-combustible metal wall panels help prevent flame spread, enhancing safety. However, panels' fire behavior varies by material, with some offering higher resistance than others, critical in design considerations.

In conclusion, commercial wall panel systems epitomize the confluence of form and function, offering scalable solutions that cater to diverse industry needs. These systems not only underscore cost-effectiveness and aesthetic versatility but also promote sustainability and ease of maintenance. By adopting such innovative systems, industries are poised to enhance operational efficiencies and aesthetic appeal, ensuring that both structural integrity and design elegance coexist harmoniously in the built environment of the future.

Philigreen, based in Huizhou and Guangzhou, specializes in premium green building panels like PVC/HPL, inorganic coated, and honeycomb panels. Using European eco-friendly tech and automation, we deliver high-quality, customizable solutions for offices, hotels, and hospitals. With 13 advanced production lines, we boost efficiency by 60% while reducing labor by 80%. Committed to sustainability, we innovate for a greener future.

Contact us for a free quote of your ideal Commercial Wall Panels!